TC11 discuses advanced refractory materials and worldwide industrial experience on glass melting furnaces.

The material properties and application problems are reported and analyzed.

Testing procedure and inspection methods for refractory materials will be recommended.

Planned activities for 2024

TC11 annual meeting planned on October 21st at Dusseldorf

Activities and planned actions

2023

TC annual meeting:

Monday, 20 December 2023 – SGR Provence

All TC11 members have been invited at Saint-Gobain Research Provence center to exchange on the topics listed below and have had the opportunity to visit the SGRP laboratories facilities.

1) The Effects of High Electric Boost on Regenerator Superstructures – Trevor Wilson

Practical experience showing the positive effect of the glass phase content (>10%) on the mullite based bricks used in the regenerators crowns & walls during lower temperatures operation.

2) Material selection for next generation combustion – Ide Tomoyuki

Development of a higher durability ab Al2O3 electrocast containing 70% a-Al2O3 with improved spalling & creep resistance for the oxy fired furnaces crowns.

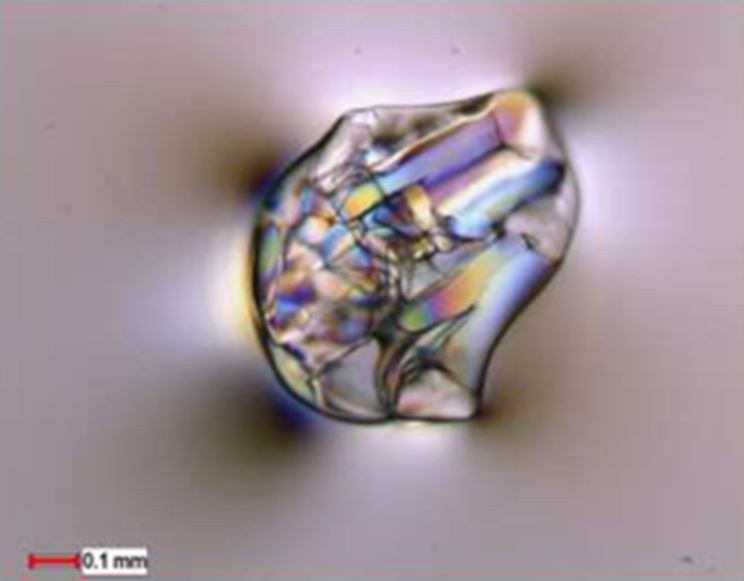

3) The effect of refractory quality on glass defects: Testing and sampling of refractories – Izmirlioglu Burak

Overview of the refractories tests including the normalised tests (CCS- Creep…) but also the new characterisation perspectives (Resonant Frequency Damping Analyser & Raman spectroscopy) for an optimised refractories selection in the glass furnaces.

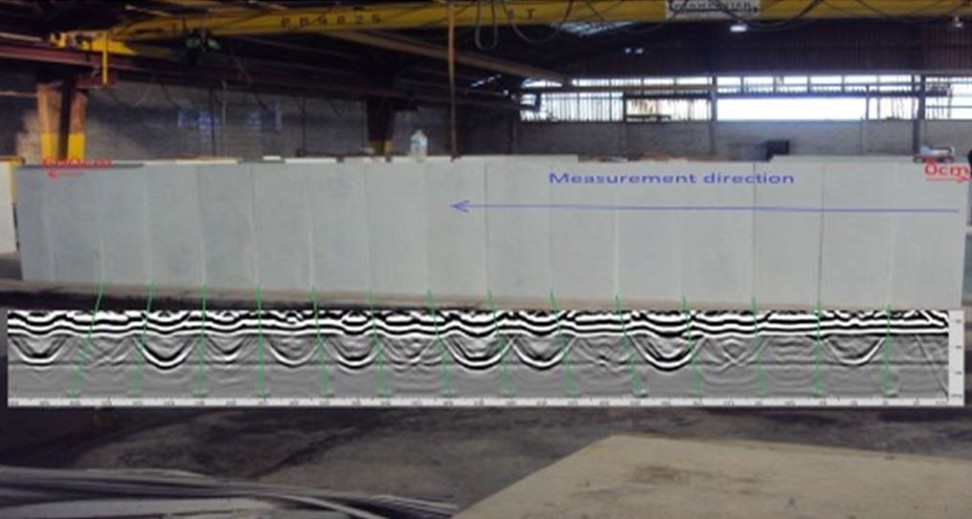

4) Bottom structure proposals to increase the thermal cycles resistance – Jean-Pierre Meynckens

AZS pavings have been monitored by GPR after the furnace campaigns. The disappearance of the pavings at the lower temperatures areas can be explained by the thermal variations and the subsequent post expansion of the AZS pavings due to the thermal hysteresis of the ZrO2 transformation. Some design improvements are suggested to overcome this problem.

5) Bottom Lining Considerations – Daniela Messina

Description of the paving types (electrocast & bonded) for use in the highly boosted furnaces. Discussions about glass corrosion, metal drop drilling resistance, electrical resistivity (measured @ RHIM Leoben), thermal expansion stability. Effect of the monolithic layers and the lower layers is evaluated in regards with the heat loss and the bottom lining durability.

6) Bottom Paving Corrosion in Hybrid & High e-Boosting Furnaces – Stephane Schaller & Michel Gaubil

Description of the 3 main types of corrosion (direct – upward & downward drilling) and bottom paving reinforcement proposals according to the furnace solicitation (standard, hybrid or high boosting). Benefits of double paving solution are detailed case by case for higher resistance.

7) Discussion about Liaison ICG TC 11 – Refractories with ISO/TC33 – Jean-Pierre Meynckens

TC11 Chair has been contacted by ISO/TC33 involved in the refractories standards publication. The first objective of the liaison is to be a platform formalizing somehow the exchange of information between the two bodies. Example of interest is the quartz evaluation in silica bricks that has been evaluated by TC11 in 2021-2022 (in the frame of RRT for silica) and that is to date a topic under development of ISO/TC33. Depending upon the willingness of TC11 members we might activate this liaison.

Meeting

September 2022 in Düsseldorf, Germany:

October 2020 in Düsseldorf, Germany

October 2019 in Venice, Italy

October 2018 in Düsseldorf, Germany

October 2017 in Istanbul, Turkey

September 2016 in Düsseldorf, Germany.

October 2015 in Eindhoven, Holland.

October 2014 in Düsseldorf, Germany.

Presentation

2022

– Crowns deformation during furnace lifetime: Jean-Pierre Meynckens

– Crowns design & material choices: Stefan Postrach/Daniela Messina

– Several approaches regarding creep (laboratories tests & long term prediction) :Christian Kunert

– Refractories for a Decarbonised World: Trevor Wilson (invited speaker)

– Hydrogen combustion and risk for superstructure refractories: Christian Kunert

– How high electrical boosting will affect glass furnaces’ refractory material : Michel Gaubil

– Float Bath Bottom Block problems (delamination, flaking, and bottom bubble generation): Melih Ustun

– Tin Bath Bottom Blocks_RHIM solutions: Andrea Roncaglia (invited speaker)

2019

Evaluation of silica testing methods:

– Presentation: Stefano Cappuzzo, Stefano Sanchetti (SSV)

– Presentation: Andrea Roncaglia (AGC)

– Presentation: Anne Jans Faber, Marco van Kersbergen (Celsian)

Worked out a silica RRT program:

– All members

Mixes

-Presentation: Refractory mixes for glass industry, Mark Taylor, Santiago Suarez (Magneco/Metrel)

2017

Sven-Roger Kahl (Ardagh Glass): The new requirements for refractories for multi-fuel hybrid furnaces

Bruno Malphettes (SEFPRO): superstructure corrosion

Rongxing Bei (RHI): Overview of all possible refractories for crown and superstructure

Burak Izmirlioglu (Sisecam): The crown and superstructure refractories and glass defects

Simone Tiozzo (Stazione Sperimentale del Vetro): The glass defects from crown and superstructure

Esref Aydin (Ex TC11 Chairman): Catscratches and Cords

AnneJans Faber (Celsian): Methods and tools to study crown corrosion and heat losses of refractory walls

2016

Rongxing Bei: DURITAL AZ58 and DURITAL K99 EXTRA for the Superstructure of Glass Melting Furnaces.

Johannes Vetter: Thermochemical Regenerator – High Efficiency Heat Recovery for Oxy-Fired Glass Furnaces.

Anne Jans Faber: Project proposal – Reducing structural heat losses at glass Furnaces.

Anne Jans Faber: New CelSian CO+ sensor for burner control.

Marvin: The production at Ling Nan refractories, China and the quality control.

2015

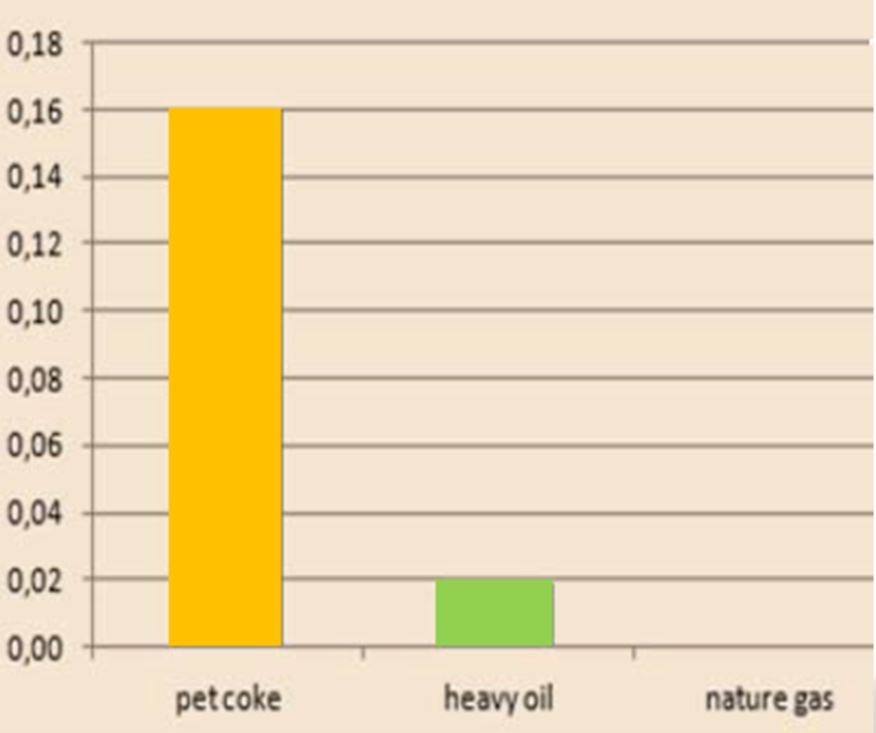

Jean-Pierre Meynckens: Effect of pet coke on refractories in glass furnace.

Michel Gaubil: Diverse industrial experience in glass furnace using pet coke.

Rongxing Bei: Regenerator Lining Concept under Pet-Coke Firing.

Stef Lessmann: Experimental device to test the refractories for regenerators.

2018

Evaluation of different test methods for blistering

– Roland Heidrich (REFEL, Italy)

– Brian Harris (NSG, UK)

– Christian Kunert (Schott, Germany)

– Kenji Matano (AGCC, Japan)

2014

Amul Gupta and Michael Dunkl: Bubble formation by AZS-refractories during startup of glass melting furnace.

Kevin Selkregg: Glass defect in glass melting tanks by AZS-refractories.

Burak Izmirlioglu: Refractories, Glass Defects and Post Mortem Works:

Next steps:

– Influence factors for blistering: study on impurities, oxidation stage of the fused cast materials

– Evaluation of new test methods for refractory materials

Committee Members

Meynckens, Jean-Pierre (AGC) Committee Position: Chair

Gaubil, Michel Committee Position: Vice Chair

Bogaerts, Michel (AGC)

Cappuzzo, Stefano (STATIONE SPERIMENTALE DEL VETRO)

Harris, Brian (NSG)

Heidrich, Roland (REFEL)

Ide, Tomoyuki Japan

Izmirlioglu, Burak (SISECAM)

Kunert, Christian (SCHOTT)

Messina, Daniela (RHIMagnesita)

Postrach, Stefan (RHIMagnesita)

Sanchetti, Stefano (STATIONE SPERIMENTALE DEL VETRO)

Schmidt, Anne Germany

Tojo, Shin (NEG)

van Kersbergen, Marco (CELSIAN)

Wilson, Trevor (DSF)

Committee Contact Details

Jean-Pierre Meynckens

AGC – Refractories Development & Coordination

Rue Louis Blériot, 12

6041 Gosselies – Belgium

+32/478.40.59.12

Members Downloads

Download Manager